What are the Different Types of Blowers and Associated Uses?

Whether you're involved in ventilation, cooling, or exhaust systems, understanding the differences among blower types can help you choose the right equipment for your requirements. In this guide, our specialists at BCB Sales & Service delve into the various types of blowers, such as centrifugal, regenerative, and positive displacement blowers, and their unique functions and uses.

Understanding Blowers: Their Functions and Uses

The primary function of a blower, however, is to amplify airflow, which in turn facilitates the expulsion of airborne pollutants such as dust and debris. This all occurs with the elevation of air or gas pressure through the centrifugal action of a rotor. Air or gas enters through an inlet, prompting the impellers (or rotors) to spin.

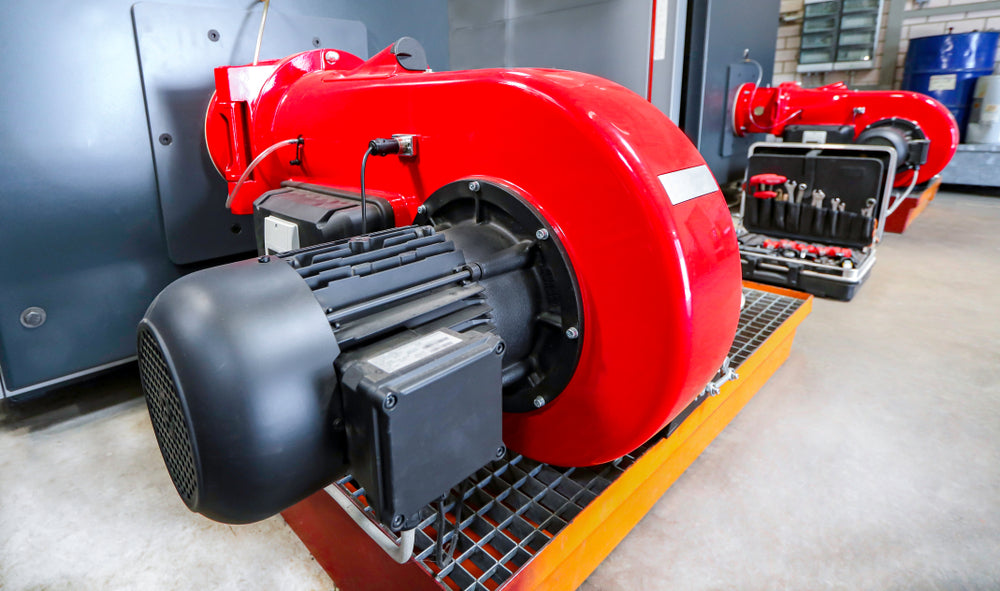

Centrifugal Blowers

As the air enters the blower's fan wheel, it is redirected by 90 degrees and exits at an increased velocity compared to its entry. This dynamic makes centrifugal blowers ideal for continuous gas transfer and scenarios requiring high pressure and adjustable flow rates, enhancing kinetic energy as the gas circulates through the system. This balances the pressure as gas is expelled and new gas enters.

A notable variant is the multistage centrifugal blower, which consists of multiple rotating mechanisms driven, typically, by an electric motor. These blowers can elevate air or gas pressure through centrifugal force. They are characterised by their ability to handle high pressures and voluminous flow rates, making them particularly effective in applications requiring the generation of significant pressure from relatively modest air volumes.

Multistage centrifugal blowers are instrumental in various sectors, including aeration processes in wastewater treatment, boosting landfill gas, and operating artificial respiratory systems in medical applications.

Regenerative Blowers

As the impeller rotates, it propels the air forward, cycling it back to the impeller's base. This method, known as non-positive displacement, effectively traps and moves air, ensuring efficient air circulation and pressure stabilisation suitable for various industrial applications.

Positive Displacement Blower

Rotary Lobe Blowers

Helical Screw Blowers

Another variant within the positive displacement blower category is the helical screw blower, which features a primary rotor that interlocks with a secondary rotor's flute. The design ensures that the rotors never touch each other. In contrast to rotary lobe blowers, helical screw blowers can generate higher air pressures and operate more quietly. They are also more energy-efficient and typically come in a sealed configuration to minimise air leakage, enhancing their operational efficiency and suitability for various applications.

High Pressure Blower

Designed to meet the rigorous requirements of up to 25 psi in pressure and up to 15,000 m3 per hour in flow, high-speed blowers parallel the functionality of centrifugal blowers but with enhanced capabilities. The dual impellers enable efficient dual suction, and when connected to a permanent magnet synchronous motor controlled by a VFD, these blowers achieve optimal speeds while maintaining precise flow control, suitable for demanding industrial environments.